D.V.POLYMERS INDIA P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to D.V.POLYMERS INDIA P.LTD.

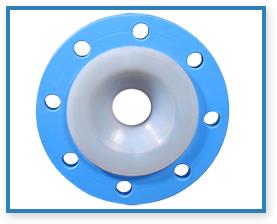

P. V. D. F. (Polyvinyledene Fluoride)

36740.jpg)

PVDF, Polyvinyledene Fluoride is a highly non reactive and pure thermoplastic fluoropolymer. It is also called as HYLAR.

PVDF is a special plastic material from the fluoropolymer family. PVDF coating is a special purpose coating that can be used in various applications that require highest purity, strength, resistance to solvents, acids, and bases and for low smoke generation during a fire event.

PVDF coated components are used extensively in the high purity semiconductor market (low extractable values), in the pulp and paper industry (chemically resistant to halogens and acids), nuclear waste processing (radiation and hot acid applications), chemical processing (chemical and temperature applications), and water treatment. This fluoropolymer can also meet specifications for the food and pharmaceutical processing industries. At elevated temperatures PVDF can be dissolved in polar solvents such as organic esters and amines, making them practical for use in corrosion resistant coatings and durable architectural finishes on building panels. PVDF coatings are easy to melt when compared with other fluoropolymers because of its low melting point of around 177°C, PVDF can be injected, molded or welded.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.